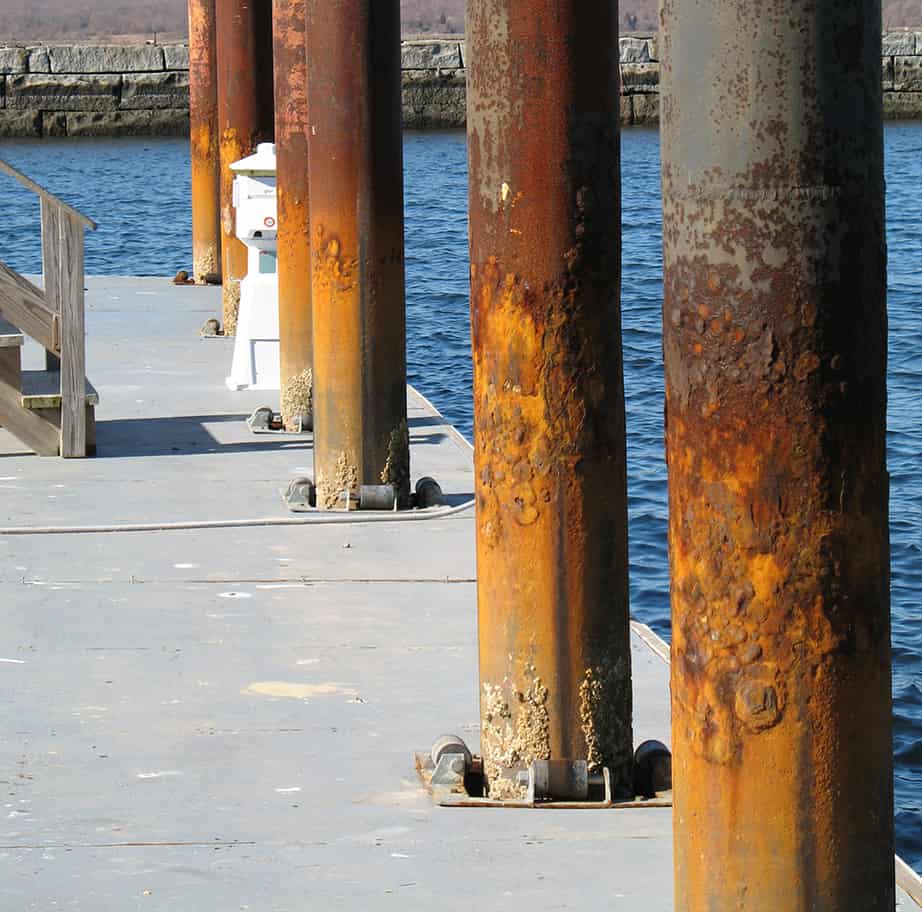

We provide long-lasting structural solutions to protect your marine investments and shorelines, as well as support your plumbing

Our Promise

Since 1989, we have been on the forefront of creating the most comprehensive, cutting-edge marine infrastructure systems and we are committed to maintaining the same level of quality and innovation for years to come.